The Secrets of the Coffee Capsules in 10 Steps

The coffee market is now clearly split into portioned coffee and Whole grain / Roast&Ground coffee. In Italy, the market share increased by 20% and ESE by 5%, when the overall market is stable. It means that the commodity, simplicity and quality of these products are satisfying more and more consumers.

The coffee market is now clearly split into portioned coffee and Whole grain / Roast&Ground coffee. In Italy, the market share increased by 20% and ESE by 5%, when the overall market is stable. It means that the commodity, simplicity and quality of these products are satisfying more and more consumers.

Now, as a roaster company or independent Barista, you want to launch your own products, how can you do that and what are the main parameters to control when developing your portioned coffee?

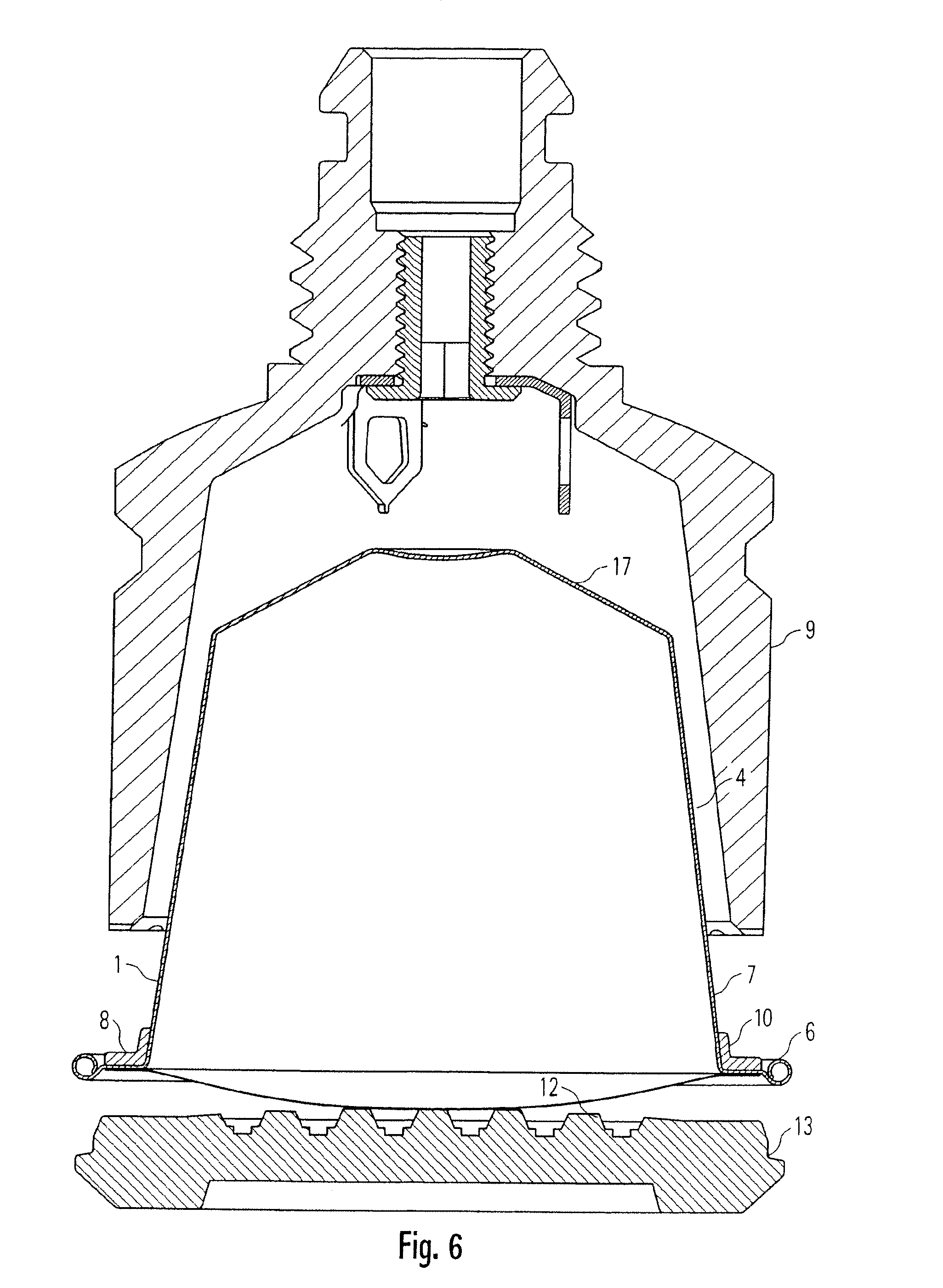

1. THE CAPSULE

Coffee enemies are Air (contains 20% oxygen), Humidity (Water) and Light (UV). All of these enemies will oxidized, modify or turn rancid your coffee. So, you need a barrier able to protect all of them.

The best one would be a totally hermetic barrier and today this kind of barrier is still metallic… Alternative materials can provide very good to good barriers. These are polylaminar films containing up to 7 sheets (PE, PP as water barrier, PVOH as oxygen barrier, etc.). The poor barriers are, of course, pre-perforated capsules.

Capsules are mainly made from 2 technologies:

– molded capsules (Nespresso®)

– thermoformed capsules (Café Royal)

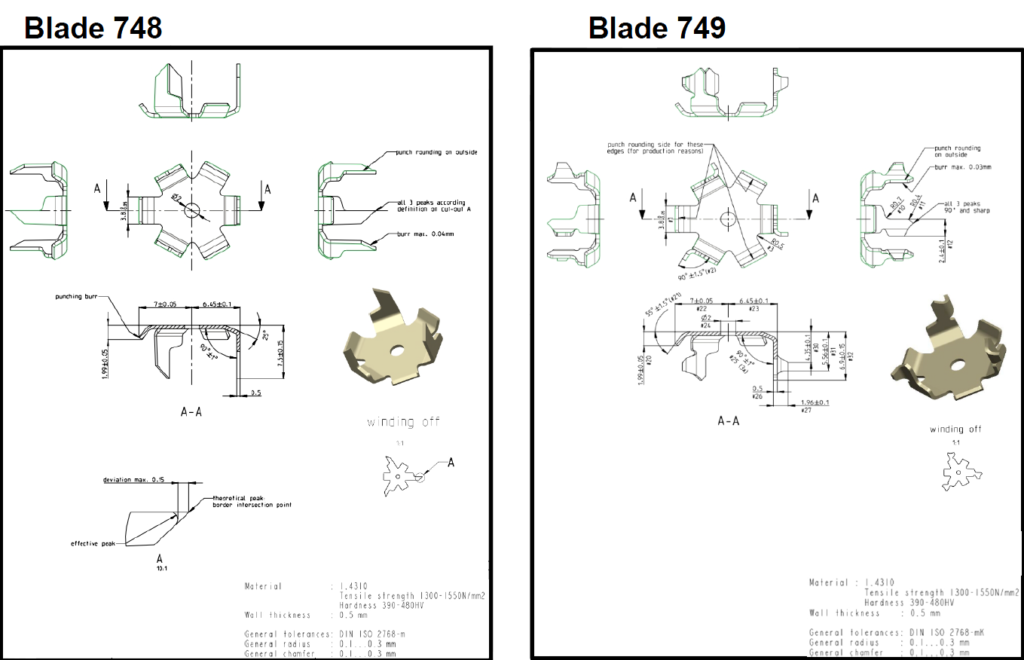

Nespresso® capsules have a special O-ring making the capsule being hermetic in the extraction head during percolation. It is a patented object still valid today. Competitors are then forced to use other system to create this hermetic structure with extraction head. Another modification has been the blades of the group head. Nespresso® changed blades for better extraction, but the new blades also have now more difficulty to perforate the compatible capsules…

Nespresso® vs Café Royal

O-ring

Nespress blades 748 vs new 749

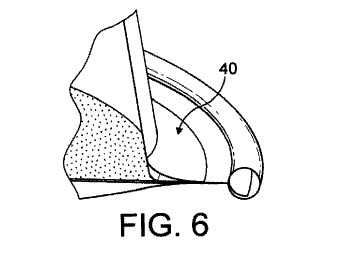

2. THE CAPSULE LID OR COVER

The « Waffle » has a big impact on making a good extraction. The lid must be well perforated by the “waffle” in order to avoid over-pressure or bad extraction. Non resilient lid materials are good candidates for the extraction. Metallic ones such as aluminum ones are still the best.

3. GREEN COFFEE – DENSITY

The choice of the green coffee should also be adapted to the capsule. As 5-6g is a low amount for a real espresso, more coffee you can put, better the beverage would be. So, choosing high density coffee will help you to put more coffee into you capsule. Moonsoned Malabar from India, is a very low density coffee. It would then very hard to fill the entire capsule with more than 5g.

Moonsoned Malabar from India (density= 670g/L) vs Yirgacheffe from Ethiopia (density=850g/L)

4. ROAST DEGREE

Most of the coffee roasters, especially the Small&Mid Caps roasters, think that it is sufficient to take their normal blends, grind them fine and introduce 5 to 6g into a capsule to make a very good capsule ! IT IS WRONG ! Extraction with a Nespresso® compatible capsule needs adapted parameters ! When you want to taste a nice single origin coffee with a V60 method, you will adjust roasting degree, grind size, quantity, etc. So, for the capsule extraction, it is the same!

5 to 6g of ground coffee is not enough to obtain a brown and nice crema, especially when extracted within 10-15 seconds. So, coffee must be roasted darker, much darker! In term of Probat Colorett 3b value, a coffee at 100 must roasted dark up to 80-85.

Example of the same coffe used as whole beans for standard espresso with portafilter and for capsules. Colour as per Probat Colorette 3b are the following: 90 for the coffee for standard espresso with portafilter and 70 for the coffee capsules.

5. « QUENCHING »

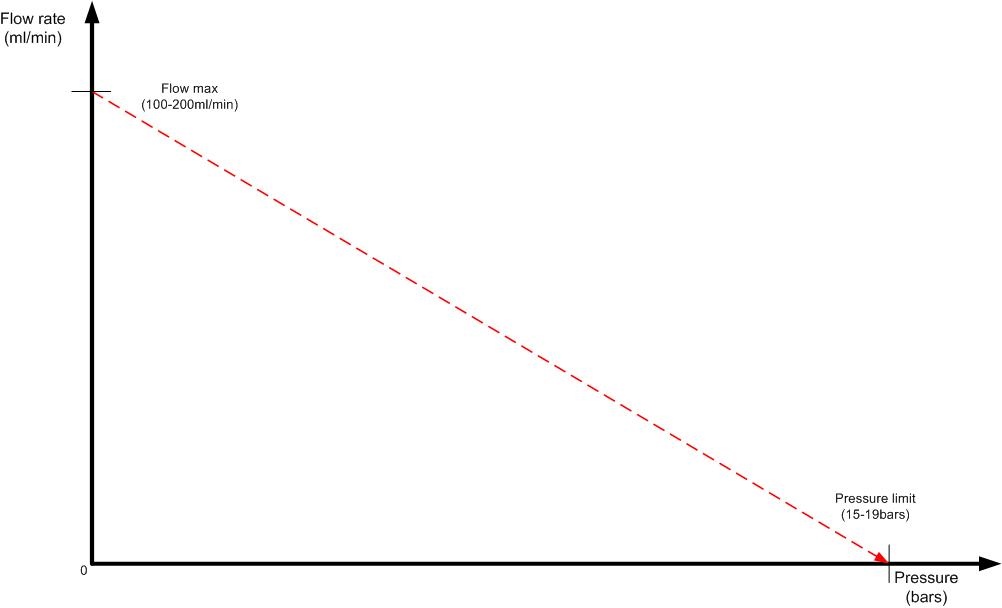

Quenching is the addition of water at the end of a roast cycle. In big batches, it allows the coffee to cool down quickly and avoid further roasting. The water quenching tends to densify the ground coffee and decreases the fine particles during grinding. This could be very attractive when fine grinding is needed. Too many fine particles tend to block the bed for a good extraction and the vibration pump force to its maximum (15 to 19 bars). Water quenching could be a “trick” to grind finer and to add weight into the capsule.

6. DEGASING

DEGASIN G is the term used for resting coffee for a few hours. During this rest, CO2, that is the most generated compound during roasting, goes out the bean. The amount of CO2 gives an indication of the freshness of the coffee. CO2 is also responsible for the crema on an espresso. The CO2 emulsion is stabilized with the arabino-galactan molecules present into the coffee beverage. In order to keep a hermetic capsule, it is important to decrease the CO2 pressure into the capsule below a critical point that will open microfractures and let the exchange between air and CO2. The coffee will then taste oxidized without crema or only a few. Standard degassing time are between 6 to 24 hours on whole beans. It is also possible to degas after grinding.

G is the term used for resting coffee for a few hours. During this rest, CO2, that is the most generated compound during roasting, goes out the bean. The amount of CO2 gives an indication of the freshness of the coffee. CO2 is also responsible for the crema on an espresso. The CO2 emulsion is stabilized with the arabino-galactan molecules present into the coffee beverage. In order to keep a hermetic capsule, it is important to decrease the CO2 pressure into the capsule below a critical point that will open microfractures and let the exchange between air and CO2. The coffee will then taste oxidized without crema or only a few. Standard degassing time are between 6 to 24 hours on whole beans. It is also possible to degas after grinding.

7. AMOUNT OF COFFEE

The amount of ground coffee will influence directly the speed of extraction and its quality. More coffee you can add in the capsule, better the extraction will be. Another frequent error is the fulfilling of the capsule. It is ESSENTIAL to let a headspace in the capsule in order to create some turbulence during the water percolation. These turbulences will make the extraction more efficient without creating channeling. So, remember: NEVER FILL THE CAPSULE TOTALLY !

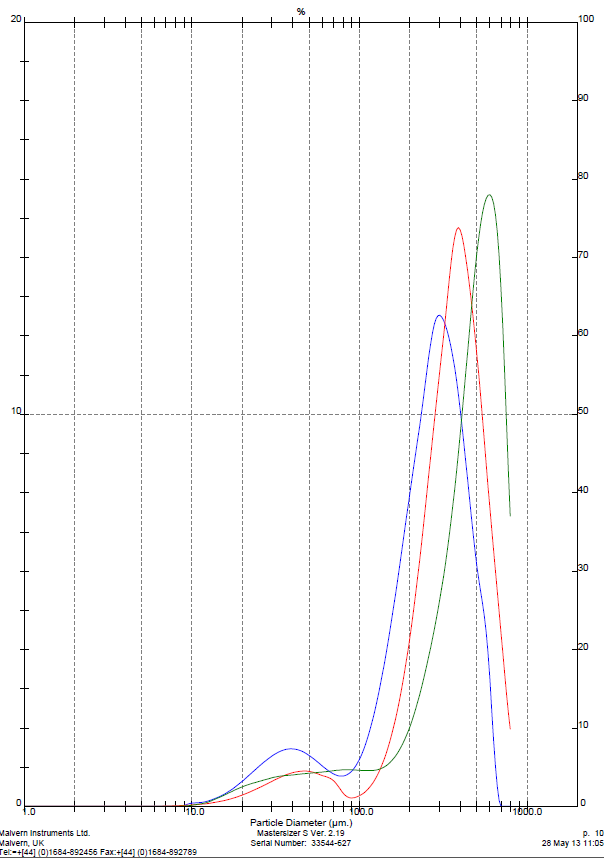

8. GRINDING AND GRINDER

The particle size distribution in correlation with the amount of coffee will define the extraction profile of the capsule. This distribution is then very important! It will also influence the pressure of extraction as the vibration pump will counter act the backpressure in order to flow through the capsule. A one stage grinder will give a very large particle size distribution and no margin to improve or correct the distribution in case of bad extraction. Then, you need at least 2, but better 3 or more grind stages. It allows to better define the best distribution for the capsule.

9. ANALYSES

In term of analyses, you need to know accurately your coffee: colour, water content, particle size distribution.

Concerning chemical food safety, mycotoxin (Ochratoxin A), Acrylamide (since April 11th 2018 via EC 2158/2017 Regulation) and Furan in the future must be determined in order to be sure to avoid any safety concern. Ochartoxin A max level is 5ug/kg in roasted coffee, Acrylamide is max. 400ug/kg roasted coffee. Furan could be problematic for capsules as it is a molecule with a low boiling point and can therefore be released when whole beans packaging is used, but not in hermetic capsules.

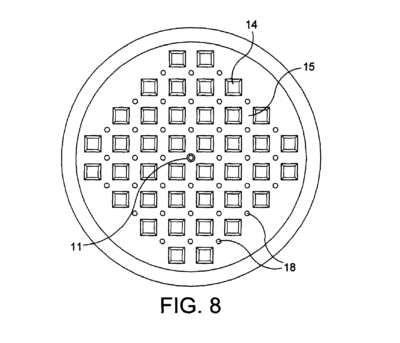

Another very interesting test is the pressure test during extraction. It can be done modifying a machine as below:

Manometer fixed on the Nespresso® machine

Graph for vibration pump pressure:

10. THE FUTURE

There is a lot of confusion about the different labels, i.e: Biodegradable, Compost, Home-Compost, etc. Different European norms classify these terms, but consumers are not always aware of the real definition. It is not the goal here to list these different norms, but I can only say that the next generation will be the Home Compost capsules with a few months shelflife. Some are already present on the market, but we don’t have enough feedback yet about the real “barrier” effect of these capsules.

Is there any difference between BIODEGRADABLE and COMPOSTABLE ?

BIODEGRADABLE and COMPOSTABLE are terms that are often confused by the consumers. They are not similar. BIODEGRADABLE means that a product can be decomposed by micro-organisms, but it does not mean that it will be transform into a good quality compost. Furthermore, biodegradability and compostability depend on the environment in which they are decomposed. Biodegradable products must be decomposed in an industrial environment within 6 months while compostable products must be decomposed in an industrial environment within 12 weeks (OK COMPOST). So, biodegradability and compostability depend on the speed of decomposition in well defined environment. For example, a biopolymer is biodegradable in an industrial compost installation, but not in water, soil or garden compost (temperature is often not high enough in our home compost installation).

What is the difference between OK COMPOST and OK COMPOST HOME ?

The products that are only certified OK compost are products that must be used in an industrial installation fo compost (temperature between 55-60°C). It means that you must not throw them in the home compost or in the garden compost.

OK compost HOME certified products are those that can be directly put in the garden or home compost.

To summarize:

BIODEGARDABLE: decomposition of min. 90% within 6 months in an industrial compost installation

OK COMPOST: decomposition and fragmentation in particles less than 2mm within 3 months in an industrial environment

HOME COMPOST: decomposition and fragmentation within 3 months in a garden or home compost installation

Example of HOME-COMPOST capsule:

CONCLUSIONS

To conclude this article about how to develop a good coffee from a capsule, I would like to insist on the following topics:

- Nespresso® capsules will never give the same result as the espresso prepared following the SCA standards. It’s a very good product, but still far from what experts define as perfect espresso.

- Capsules enemeies are: aire, light and water. So, barrier material must protect from all these 3 enemies.

- Coffee MUST BE roasted differently for this specific method of extraction

- Grinding is also very important and will define the strength and extraction of the final beverage (see SCA modules for the definitions of strength and extraction).

- Production of capsules is an industrial process that needs some laboratory equipments such as colourmeter, granulometer or moisture analyzer.

Finally, new types of capsules are entering in the market with new barrier properties and more ecological characteristics that should attract future consumers. It would probably stay as a niche market, but it will grow enough to be considered as a real chance for some small and mid cap companies or even for micro roasters.

If you need more information or want to know more about capsule technologies, please contact coffebi.